Types of Springs

There are two types of springs, coil springs and non-coil springs. The meanings are quite obvious due to the names.

Non-coil springs are not coiled in the way we usually think of a spring. Perhaps the best example is the suspension springs used on a trailer. These are sometimes called Slipper Springs.

Coil springs have a coiled design and look more like the typical spring we are used to seeing – the type that pops out of a broken ballpoint pen. Generally, coil springs are manufactured from a single strand of metal that has been wrapped around a cylinder to form a helix. It’s this helical design that defines a coil spring.

There are at least four types of coil springs:

Compression Springs

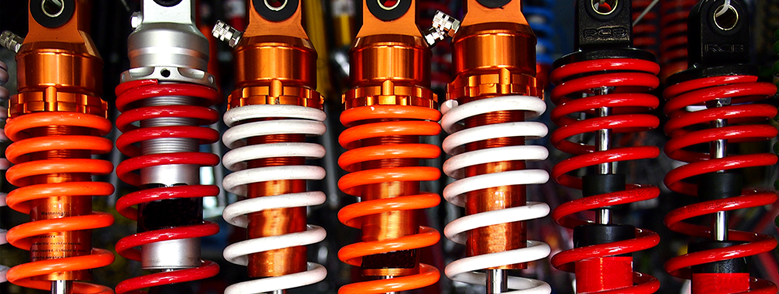

When most of us think of springs, we are picturing a compression spring. These are coil springs which, when experiencing a compression load, compress and become shorter. When the force is released, they spring back to their original shape, sometimes with a significant amount of force.

Compression springs may be coiled left or right hand depending on their use. They also have several end options.

Most spring manufacturers will design a compression spring tailormade for unique applications.

Find out more about compression springs.

Tension Springs or Extension Springs

Tension springs and extension springs are tightly wound coils that are designed to operate in tension. The spring stretches to a specific length as the load/force is applied to it.

The difference between a tension spring and a compression spring is very simple. A tension spring is designed to bring components together; a compression spring is designed to keep components apart.

In an unloaded position, the coils of a tension spring are touching. The spring will be attached to some other equipment with either a loop or hook at the ends. When force is applied, the spring stretches. When the force stops, the spring returns to its original shape.

The lever mechanisms within most doors contain a tension spring. Another good example is the springs of a trampoline which, in their resting state, sit with the loops touching. However, when someone bounces on the trampoline, the spring stretches. The force pulling the spring back into place is what creates a great bounce.

Find out more about tension springs.

Variable Coil Springs

Variable coil springs are also known as progressive rate springs. Their name arises because they work with a variable rate. This is enabled because they are manufactured with different distances between their coils. The coils may be fairly widely spaced at one end of the spring and draw closer together at the other end.

This variation in coil distance means that, when a variable coil spring is compressed, its rate of compression varies throughout its length. This compares with a typical compression coil spring which has the same distance between its coils, and so has the same rate of compression throughout the entire spring.

Variable coil springs are popular in vehicle suspensions because they have the potential to improve a vehicle’s ride quality over a wide load range. Whereas a coil spring with only a single rate will ride rougher down the road, variable coil springs compress gradually and so produce a smoother ride.

Torsion Coil Springs

Torsion coil springs are manufactured to withstand or resist twisting actions. A common example is a spring used on a manual garage roller door. When twisted along its axis, a torsion spring will retain its energy and so must be locked in place somehow. When the lock is removed, the spring will release its energy. In the case of a garage roller door, this makes pulling the door open or closed easier because the spring is helping with the load.

Another example is the spring on a mousetrap which can be twisted and locked in place until an unsuspecting mouse trips the trap and releases the spring which snaps the trap shut.

Summary

There are many types of coil springs manufactured in Auckland. It is the coil design that differentiates them from other types of spring. We’ve listed four of the most common coil springs.

Because each spring type has a different use, a spring manufacturer will need to know the precise use and loading of a spring before designing and crafting it.

National Springs and Wire Products NZ Ltd is New Zealand’s most comprehensive solution provider for springs and wire forms. Our unrivalled in-house design and development expertise ensures that you get the right solution for your specific project. Our state-of-the-art CNC equipment delivers high-quality, accurate and consistent product flow – fast.